Main Advantages:

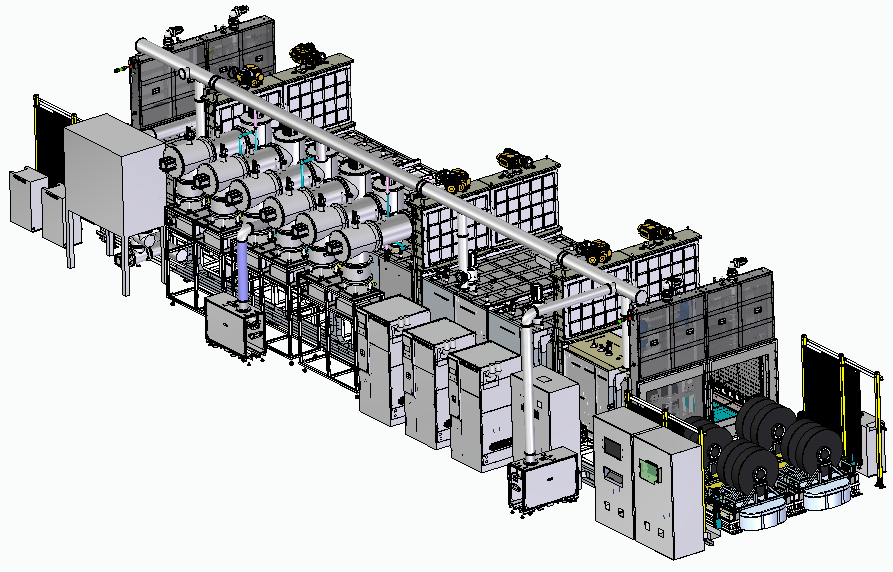

Designed specifically for high-volume drying of cathode and anode electrode rolls in lithium battery manufacturing, meeting the core drying requirements of the electrode preparation process

Incorporates a fully automated tunnel-style production line design, enabling non-stop continuous operation and enhancing production fluency and system automation

Utilizes uniform forced air circulation to achieve thorough and even heating of wide-format electrode rolls, improving drying efficiency and product consistency

The system features a broadly adjustable temperature control mechanism, maintaining stable temperature accuracy throughout the drying process and adapting to various process windows

Drying time can be flexibly configured according to process requirements, combined with uniform thermal distribution within the chamber to ensure consistent and controllable drying results

The equipment chamber demonstrates excellent airtight performance, effectively preventing external gas infiltration and ensuring the drying process occurs in a stable, controlled atmosphere